MARANELLO, ITALY—The E-Building is one of the newest on Ferrari's sprawling factory complex. One of the first LEED-certified buildings in Italy, the gleaming white interior is the latest in flexible factory design, capable of assembling any model in the automaker's range. And from next year, that will include Ferrari's first electric vehicle.

It's a momentous occasion for Ferrari, and one it's taking its time over—although it has now briefed us on some powertrain and chassis details, we'll have to wait until next year before seeing the interior or exterior of a car that it's calling the Ferrari Elettrica—for now at least.

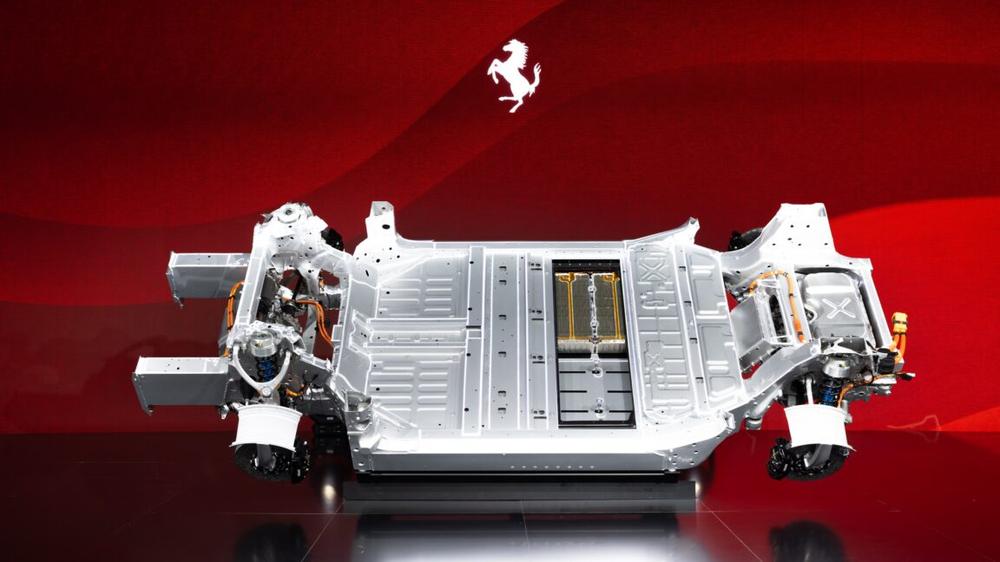

Ferrari says it considered an all-electric two-seater or even something with occasional rear seats, but the performance benefit of an electric powertrain wasn't enough to offset the added mass for either of those applications. Those calculations did work out in favor of a four-seater, though; the battery pack lowers the center of gravity by 3.1 inches (80 mm) compared to an internal combustion engine powertrain and reduces the polar moment of inertia by 20 percent.

However, the Elettrica won't be massive. While we don't know most of the exterior dimensions, the wheelbase is 116.5 inches (2,960 mm)—slightly less than a Hyundai Ioniq 5—and Ferrari says that the Elettrica features very short front and rear overhangs. Seventy-five percent of the aluminum used for the chassis (and the body panels) is recycled, helping save 6.7 tons of CO2 per car.

F1 influence

Ferrari has been working with electric powertrains since the introduction of hybrid systems to Formula 1 in 2009. The motors here aren't direct copies of the ones you'd find in Ferrari's F1 racers, but the influence is there—like the Hallbach arrangement of the magnets in the rotor. Think of it like the Konami code for magnet orientation, except here it keeps the magnetic field concentrated on the stator. A thin carbon sleeve helps contain the magnets in the rotor, and the stator windings are embedded in a vacuum-impregnated resin that has much greater thermal conductivity than air.

There are four electric motors, one for each wheel. At the front, the two 140 hp (105 kW) motors share a single inverter, mounted atop the drive unit, which fits in the compact space between the front chassis rails, just behind the crash structures. Depending on the drive mode, the front axle can be disconnected entirely from the motors via clutches for greater efficiency. These motors can spin to 30,000 rpm and have an efficiency of 93 percent.

The rear drive unit features a pair of more powerful 415 hp (310 kW) motors, each with its own inverter but again packaged together for better volumetric and weight efficiency. The rear motors spin at up to 25,000 rpm and have the same 93 percent efficiency as the front motors. For those keeping score, the motors have a power density of 1.9 hp/lb (3.23 kW/kg) at the front and 2.9 hp/lb (4.8 kW/kg) at the rear.

Like the drive units, the battery pack is made in-house, although the NMC pouch cells are supplied by SK On. Robots assemble 14 cells into a module, with 15 modules making up the Elettrica pack—13 in a slab with another two at the rear underneath the back seat. Ferrari said it went for a modular approach to future-proof the Elettrica; more than 90 percent of the cars it has made are still on the road, and it wants that to be true of its EVs as well, so it should be possible to repair the battery of the EV in the future. (This reasoning is why Ferrari rejected using cylindrical cells for the Elettrica, or a cell-to-pack design for the battery.) Decades from now we may even see Ferrari design a new battery to keep classic Elettricas on the road.

The pack has a gross capacity of 122 kWh, with a pack power density of 195 Wh/kg. Specific energy density is 280 Wh/L, with a power density of 1.9 kW/L. Peak output for the pack, which operates at 800 V, is 1,113 hp (830 kW). That should translate to a 2.5–second 0–62 mph (0-100 km/h) time and a top speed of more than 192 mph (310 km/h), Ferrari told us. It will DC fast-charge at rates of up to 350 kW, which should add 70 kWh in 20 min, we're told. Like the hardware, Ferrari designed the battery monitoring system and cell supervision software entirely in-house.

It has to feel like a Ferrari

Longitudinal acceleration. Lateral acceleration. Braking. Sound. Gear change. Those are the five elements that Ferrari considers necessary to imbue a car with "driving thrill," and this EV will be no different. Longitudinal acceleration has mostly been addressed already. Controlling lateral acceleration, and the car's ability to corner, is partly the job of a new third-generation active suspension system.

Where other OEMs might have gone for air springs or magnetorheological dampers, here you'll find coilover spool valve dampers, which use a ball screw controlled by a 48 V electric motor to control ride height as well as bound and rebound. The setup is a refinement of that found in the Purosangue SUV and the F80 hypercar, but with a greater pitch on the ball screw that better controls vertical motions.

Additionally, the vehicle's dynamic controller (operating at 100 Hz) and the inverters allow Ferrari to precisely control the amount of power and torque sent to each wheel as well as each corner's suspension behavior. And there's independent rear-wheel steering of up to 2.15 degrees; the system can counter-steer to the front wheels to increase agility, steer together with the front wheels at higher speed for directional stability, steer just a single wheel if needed, or increase the toe-in when driving in a straight line.

Regenerative braking can send up to 500 kW back to the battery pack, with a maximum regen deceleration of 0.68 G before the carbon-ceramic friction brakes take over.

Since there's no internal combustion engine to mask road noise and other NVH (noise, vibration, and harshness), Ferrari had to pay particular attention to minimizing their intrusion into the cabin. For the first time in a Ferrari, the rear suspension (and the drive unit) is fitted to a subframe, which in turn is mounted to the chassis via elastomeric bushings.

And it has spent a lot of time thinking about the car's sound. There's no faking the noise of cylinders and combustion; instead an accelerometer inside the rear drive unit acts like the pickup in an electric guitar, detecting certain frequencies that are then amplified. Like Porsche with the Taycan, Ferrari's engineers were resolute that there is no fakery going on, just enhancing the natural sounds of the power electronics and transmission.

Finally, Ferrari has given the Elettrica a simulated paddleshift transmission, similar to the one you'll find in the Hyundai Ioniq 5 N. Here it's called Torque Shift Engagement, but the idea is the same: the paddles on the steering wheel toggle through five different maps of power and torque, as well as lift-off regenerative braking to recreate the experience of changing gears in a conventional powertrain.

More details, including the Elettrica's price, should follow next year.

Tomahawk deliveries could force Russia to 'sober up' and negotiate, Zelensky says

Tomahawk deliveries could force Russia to 'sober up' and negotiate, Zelensky says